The Future of Style: Exploring DTF Printing Innovation in the Textile Sector

Recently, the fabric industry has witnessed a marked shift in the direction of innovative innovations that are reshaping the landscape of fashion production. Amongst these developments, Direct to Movie (DTF) printing modern technology has arised as a promising contender, supplying distinct capabilities and possibilities for developers and suppliers alike. This advanced printing approach has triggered passion due to its potential to transform conventional textile printing processes. As we explore the effects and opportunities of DTF modern technology in the realm of fashion, it ends up being evident that its assimilation could redefine sector criteria and pave the way for a new age of creative expression and effectiveness.

Evolution of Textile Printing

Throughout history, the advancement of textile printing has actually been a testimony to the cutting-edge improvements in this complex art kind. From the ancient civilizations making use of techniques like block printing to the digital revolution of today, textile printing has actually consistently pushed boundaries. The origins of textile printing can be traced back to China around 220 ADVERTISEMENT, with the use of wooden blocks to publish on silk fabrics. As the craft infect other components of the globe, brand-new methods such as display printing and roller printing emerged during the Industrial Change, revolutionizing the textile market - DTF Printing.

The intro of digital fabric printing in the late 20th century marked a significant shift towards more functional and sustainable printing methods. The advancement of textile printing showcases an abundant background of creative thinking, ingenuity, and technological progress in the globe of fashion and style.

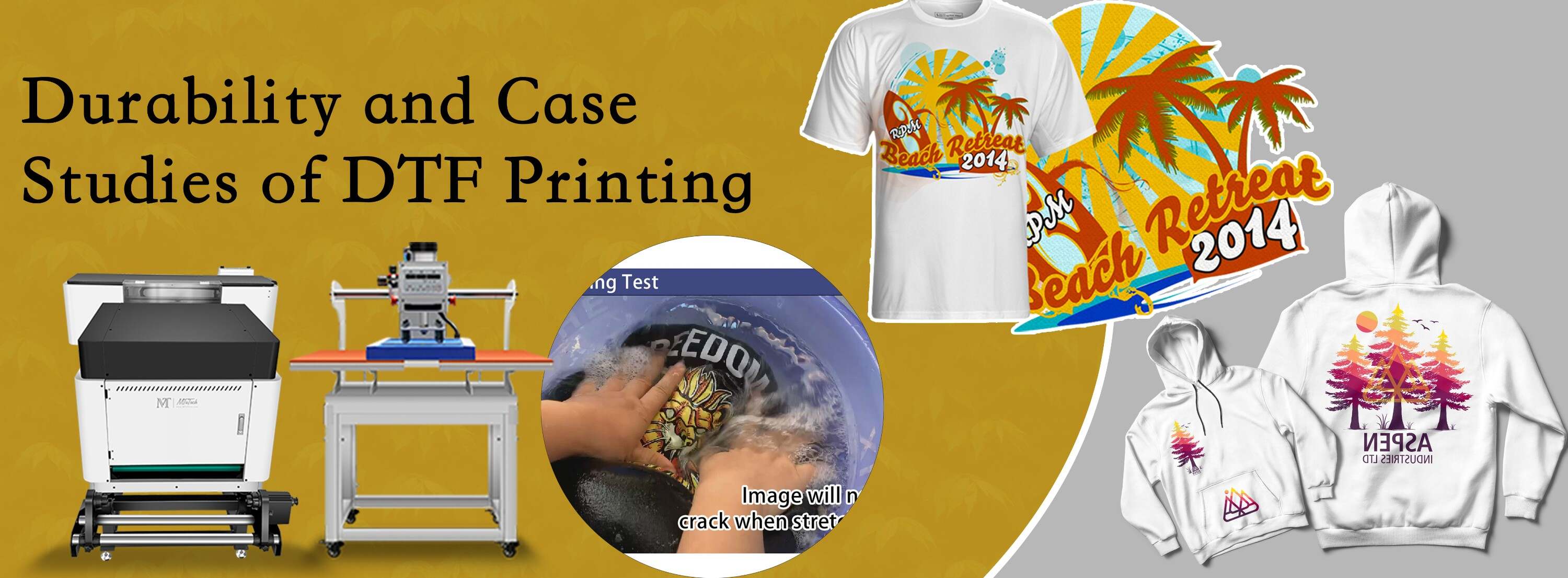

Benefits of DTF Modern Technology

With the evolution of fabric printing strategies from ancient techniques like block printing to modern-day innovations such as electronic printing, the introduction of Direct-to-Fabric (DTF) innovation has actually considerably boosted the effectiveness and sustainability of textile printing procedures. One of the primary benefits of DTF innovation is its capability to directly publish styles onto fabric without the need for transfer papers, which reduces waste and simplifies the production process. Furthermore, DTF printing permits greater shade vibrancy and information precision compared to typical approaches, allowing textile manufacturers to develop top quality and elaborate designs effortlessly.

Moreover, DTF innovation is known for its convenience, as it can be made use of on various sorts of fabrics, including all-natural fibers like cotton, silk, and woollen, in addition to synthetic products such as polyester and nylon (DTF Printing). This versatility opens up a large range of opportunities for manufacturers and developers to trying out different appearances and products, bring about more one-of-a-kind and cutting-edge items in the garment industry. On the whole, the implementation of DTF modern technology stands for a substantial development in fabric printing, offering various advantages that add to the future sustainability and imagination of the sector

Sustainability in Style Production

Highlighting environment-friendly practices is critical in contemporary style production, straightening with the expanding customer need for sustainable items. Recently, the garment industry has faced increasing scrutiny due to its substantial environmental impact, consisting of extreme water usage, chemical contamination, and textile waste. As an action, several fashion brand names are now integrating sustainable methods into their manufacturing procedures to minimize injury to the atmosphere.

Sustainability in style manufacturing encompasses numerous facets, such as using recycled and organic materials, decreasing energy consumption, carrying out honest labor methods, and promoting transparency throughout the supply chain. Additionally, developments in innovation, like DTF printing, deal chances to even more enhance sustainability in fabric production. This innovation allows specific printing on materials, lowering this content ink wastefulness and water use compared to traditional printing techniques.

Layout Flexibility and Personalization

Additionally, DTF printing assists in personalization on a scale formerly unattainable, allowing for customized clothes and one-of-a-kind pieces customized to individual choices. Consumers can now proactively join the layout process, creating garments that show their design and personality. This customization not just boosts the consumer experience yet also check my site advertises a sense of exclusivity and originality in a market saturated with mass-produced apparel. Overall, DTF printing modern technology reinvents the style landscape in the fabric industry, offering unlimited possibilities for innovative expression and individualized fashion.

Impact on Supply Chain & Market Trends

DTF printing technology in the textile market is improving supply chain characteristics and affecting market patterns through its effectiveness and customization abilities. By enabling on-demand printing and eliminating the demand for big stocks, DTF technology streamlines the supply chain procedure.

In addition, the customization capacity of DTF printing technology is revolutionizing the marketplace fads in the fabric industry. Consumers progressively look for individualized and one-of-a-kind products, and DTF allows brand names to offer bespoke designs cost-effectively. This personalization ability not just improves client contentment yet likewise opens up new opportunities for services to accommodate specific niche markets and separate themselves from competitors. Consequently, DTF technology is driving a shift in the direction of more customer-centric and ingenious methods within the fabric industry, shaping the future of fashion.

Conclusion

Finally, DTF printing modern technology is transforming the textile industry by using countless advantages such as design liberty, customization, and sustainability. This innovative innovation is improving the future of style manufacturing, influencing supply chains, and driving market patterns towards a lot more effective and environment-friendly techniques. As the industry remains to progress, DTF printing will play a crucial duty fit the means fabrics are produced and eaten in the years to come.

From the ancient people utilizing methods like block printing to the digital transformation of today, go to the website textile printing has actually constantly pushed limits. As the craft spread to other components of the world, new techniques such as screen printing and roller printing emerged throughout the Industrial Change, transforming the fabric industry.

The introduction of electronic fabric printing in the late 20th century noted a considerable change in the direction of more flexible and sustainable printing approaches.With the advancement of fabric printing strategies from ancient techniques like block printing to modern developments such as electronic printing, the intro of Direct-to-Fabric (DTF) innovation has actually substantially enhanced the performance and sustainability of textile printing procedures (DTF Printing).In feedback to the vital change in the direction of sustainability in fashion manufacturing, the fostering of innovative technologies like DTF printing not only addresses ecological worries yet likewise opens up avenues for unparalleled design liberty and personalization in the textile sector